GEOTECHNICAL INSTRUMENTS AND

STRUCTURAL HEALTH MONITORING

SISGEO SPECIALIZES IN THE DESIGN, MANUFACTURE AND INSTALLATION OF HIGH-PRECISION MEASURING INSTRUMENTS FOR CIVIL AND GEOTECHNICAL ENGINEERING APPLICATIONS.

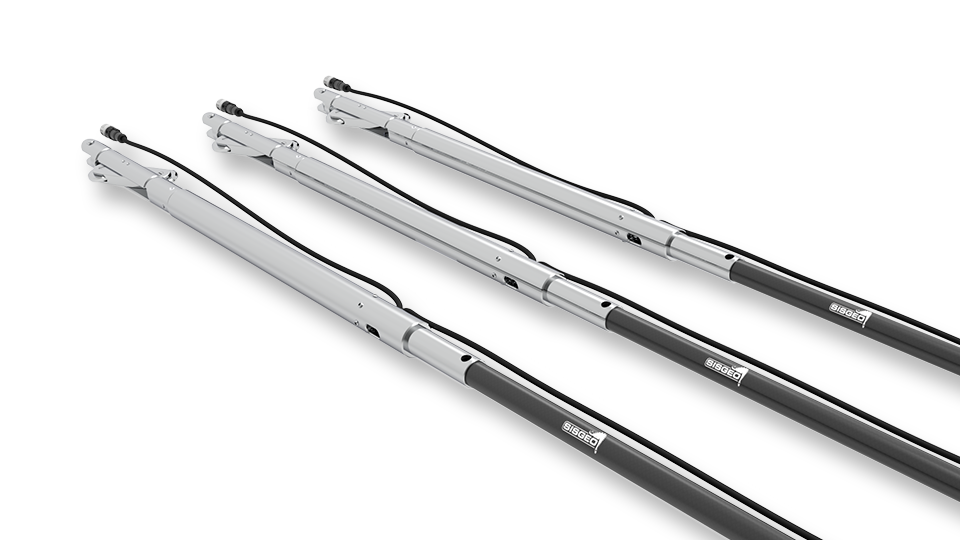

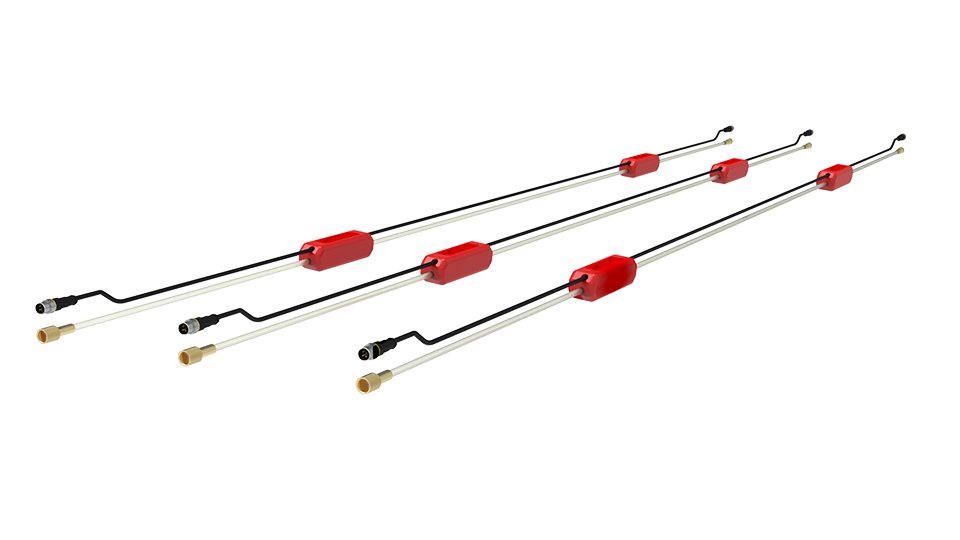

Sisgeo designs and manufactures a full range of reliable and high quality monitoring instruments such as piezometers, inclinometers, tiltmeters, extensometers, crackmeters, pressure and load cells, settlement gauges, strain gauges, thermometers, pendulum systems, readouts and dataloggers.

Over the years, SISGEO has distinguished itself among the international excellences thanks to a tight and highly motivated working group, who devoted itself with passion and creativity to design and manufacture high quality instruments to meet the broader needs in the field of civil engineering. Experience is the solid foundation from which Sisgeo start every day to develop our products and services with a constant focus on continuous innovation and attention to the sector’s future needs. Over the years, SISGEO has become a recognized brand for quality, reliability and innovation.

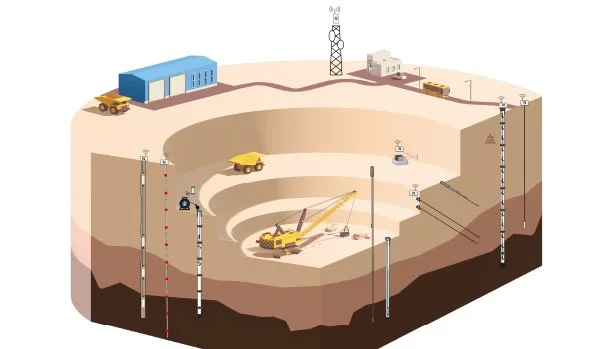

WHAT ARE THE CHALLENGES IN MINE MONITORING?

Some of the main topics and challenges in geotechnical mine monitoring include:

Ground stability: geotechnical mine monitoring is primarily focused on monitoring ground stability to prevent ground subsidence, rockfalls, or landslides, which can endanger mine workers and damage equipment.

Rock mass characterization: the behaviour of the rock mass surrounding a mine is critical for the safety and stability of mining operations. Geotechnical mine monitoring involves characterizing the properties of the rock mass, such as strength, deformation, and permeability, to assess its behaviour and detect any changes that could impact mining operations.

Slope stability: mining operations often involve excavating tunnels and working underground, which can impact the stability of slopes and increase the risk of slope failure. Monitoring slope stability is essential to prevent structural failure and ensure worker safety.

WHAT IS TAILINGS DAMS MONITORING?

A tailings dam is a structure used in mining operations to store waste material, or tailings, that is produced during the processing of mineral ores. Tailings are the finely ground rock particles and other materials that are left over after the desired mineral has been extracted from the ore.

The design and construction of tailings dams are critical to ensure their stability and prevent environmental hazards such as dam failure, which can lead to catastrophic consequences such as flooding and pollution of waterways.

Geotechnical and hydrological monitoring are important aspects of tailings dam management to ensure the stability and safety of the dam and to prevent environmental damage.

Geotechnical monitoring involves the use of instruments to verify the stability and behaviour of the dam, including its foundation, embankment, and slopes. This includes measuring parameters such as movement, settlement, and deformation of the dam and surrounding soil, as well as the presence of potential failure mechanisms such as cracks or fissures.

Hydrological monitoring involves the measurement of water levels and flow in the tailings dam and the surrounding environment. This includes monitoring the water levels in the tailings pond to prevent overflow or breaches, and monitoring water pressure under the pond.

The data collected from these monitoring activities can be used to assess the stability and safety of the tailings dam, to identify any potential risks or hazards, and to inform decision-making related to the operation and maintenance of the dam.

WHAT ARE THE CHALLENGES IN TUNNEL MONITORING?

Tunnels monitoring typically involves measuring various parameters to assess the stability and safety of the tunnel. Some of the subjects that may be monitored include:

Ground and rock deformation: monitoring ground and rock deformation can help identify any potential instability or movement in the tunnel’s surroundings. This involves measuring changes in slope, settlement, and heave using inclinometers, extensometers, and other sensors.

Groundwater pressure and flow: monitoring groundwater pressure and flow can help identify potential hazards such as seepage or flooding. This involves measuring pore pressure, water levels, and flow rates using piezometers and flow meters.

Structural deformation: monitoring the deformation of the tunnel itself can help identify potential structural issues such as cracks or movements. This involves measuring displacement and strain using sensors such as strain gauges and tiltmeters.

During tunnel excavation, it is important to also monitor the buildings and ground above the tunnel to ensure their stability and safety. Some of the measurements that can be taken include:

Settlement: vertical displacements occurs when the ground above the tunnel sinks moves due to the excavation process. Measuring settlement using instruments such as extensometers or topographic survey can help identify any potential issues and determine whether corrective action is necessary.

Groundwater levels: tunnel excavation can cause changes in the groundwater levels, which may affect the stability of the ground above the tunnel. Monitoring groundwater levels using piezometers can help identify any potential issues and determine whether corrective action is necessary.

Crack monitoring: tunnel excavation can cause cracks to form in nearby buildings and structures. Monitoring these cracks using crack gauges or other sensors can help identify any potential issues and determine whether corrective action is necessary.

Tilt monitoring: tunnel excavation can cause the ground to tilt, which may affect nearby buildings and structures. Monitoring tilt using tiltmeters, in-place inclinometers or extenso-inclinometers can help identify any potential issues and determine whether corrective action is necessary.